In 2010, the Dutch company Océ joined the Canon group of companies. Océ Technologies merged with Canon in a non-traditional way, when a large industrial giant absorbs a smaller player. This deal became a kind of symbiosis, when both partners were the winners. Canon had a wealth of experience in producing multi-color digital printing systems and office equipment, as well as serious research and development in image processing. Océ Technologies has a leading position in the design and manufacture of large format and inkjet equipment. The merger allowed the joint venture to become the world leader in the digital printing market. At the same time, Océ remained as an independent unit with the same staffing structure.

The latest generation of printing machines for the printing business, Océ has developed on the basis of its previous experience with the use of innovative piezoelectric print heads DigiDot. Due to the multi-level modulation, very small ink drops ranging in size from 2 to 12 picoliters are created at the exit of the nozzles. This allowed us to obtain the most smooth color transitions and accurate color reproduction with economical ink consumption.

Reference:

Océ was founded in 1877. Initially, it was a family business manufacturing equipment for the dyeing of butter and margarine. In 1919, Louis van der Greenten (the founder's grandson) became interested in extending the life of the photosensitive layer of paper for creating drawings. In 1927, he invents paper with a new coating that does not contain ammonia and azo compounds, and calls it OC (Ohne Componente), which means "without components." In the same year, the company is registered on the local stock exchange. To register, according to the rules of the exchange, the name must consist of at least three letters. Therefore, taking the OC abbreviation for the base, the company registered as Océ.

Since 2010, Océ has been part of the Canon group of companies. In 2017, the company celebrated its 140th anniversary.

In this review, we look at the

VarioPrint i300 ,

ColorStream 6000 and

ProStream inkjet printers with DigiDot heads. Where models VarioPrint i300 and ColorStream 6000 are typical representatives of their model lines, and ProStream is the latest development of the company, announced in February 2017

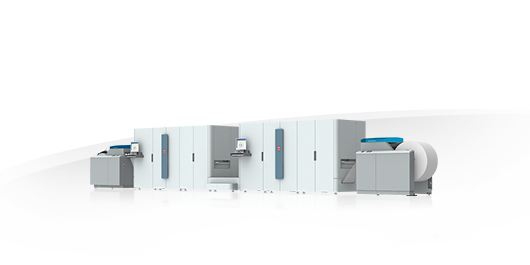

Océ VarioPrint i300

Today, more than 100 VarioPrint i300 systems are installed worldwide. For more than two years more than 1 billion pages have already been printed on this equipment.

Inkjet printing machine VarioPrint i300 is designed for color and black and white sheet printing. The use of a number of technologies in the design of the machine, which we describe next, allows you to print with high quality, perceived as 1200 dpi.

The speed of monochrome printing reaches 300 sheets of A4 format per minute. Monthly productivity of the car is from 1 000 000 to 10 000 000 prints A4. This indicator is not inferior to the average performance value for similar sheetfed presses of this class.

As a competitive advantage, Océ did not choose to increase equipment productivity, but focused on quality and advanced printing. This task was implemented with the help of a

number of technical solutions applied in the technological cycle:

- Air feed paper sheets from trays . They enter the perforated conveyor belt, under which a vacuum is created. Due to this, the sheet is evenly pressed against the entire surface of the conveyor, forming a perfectly flat plane. As a result, the print does not distort the pattern. During transport to the print area, the feed control system rejects and removes crumpled and off-spec sheets.

The VarioPrint i300 uses DigiDot piezoelectric print heads to create variable ink drops from 6 to 12 pl. The drop size changes due to the multi-stage modulation of the signal applied to the piezoelectric element. - Resolution . With visual perception, the print looks like 1200 dpi, but in fact the head realizes 600 dpi thanks to accurate dosing of drops.

This is a good indicator of the capabilities of DigiDot printheads. In addition, the developers took care of maintaining the quality of the image during the printing process in the form of continuous quality control. - Continuous quality control . The line has built-in quality controls. During printing, the printed image is constantly scanned. Detected gaps in print due to blockage or malfunction of the nozzles are corrected in real time by changing the mode of operation of neighboring nozzles.

- Automatic cleaning . During the print pause, the printhead is automatically serviced without operator intervention. The maintenance process consists in cleaning the nozzles from the protruding ink residues with a special scraper and then wiping them with a moistened cloth, stretched over the rollers.

In addition to the basic features, we recommend using

additional options that improve print quality and optimize production costs.

- ColorGrip function can be connected optionally. It consists in applying a special composition to the carrier in order to prevent the spreading and irregular absorption of ink into paper, which reduces image clarity. The ColorGrip feature allows you to use coated paper and get offset printing on it, reducing the cost of the printed product. ColorGrip also provides the ability to print on paper with special processing. VarioPrint i300 machines work with paper weighing 60-300 g / m2 and formats from 178 x 254 mm (with optional guide) to 353 x 500 mm (B3 format).

As standard, the VarioPrint i300 comes with one module for feeding paper and one large capacity drive. Optionally, the second and third modules are added, and the second large-capacity drive. The standard capacity of trays is 4,600 sheets of paper weighing 80 g / m2. - Finishing processing of printed materials is presented by the BLM600 - a system for creating booklets with a thickness of up to 224 pages or a dynamic perforator Tecnau TC1530 for creating vertical and horizontal microperforations. You can choose the option of finishing the printed products based on the needs of your printing production. In each model, only one finishing device is possible.

- Prepress. To pre-set the print, connect the Océ TrueProof system, which acts as a virtual printer. With it, you can check and adjust all image settings and color matching before it is transferred to paper. This allows you to save time and refuse to test print.

Inkjet printing machine is running the controller PRISMASYNC. The following printer data formats are supported: PDF 1.7 (Extension Level 3), PDF-X (support APPE 3.x RIP), PDF / VT (level 1), PPML, IPDS IS / 3.

Océ ColorStream 6000 Chroma

The ColorStream 6000 model belongs to universal high-speed role inkjet printing machines.

Main characteristics:

- Performance . In monochrome mode, print performance reaches 150 m / min. Optionally, paper can be stacked with a capacity of up to 505 sheets of A4 format per minute, which is more than 1.5 times the performance of the VarioPrint i300 press. With full-color printing, the speed varies from 48 to 127 m / min.

- Characteristics of the print head . On the machines of the ColorStream series, DigiDot printheads are installed with a setting of up to 6 colors. At the same time there is the possibility of using protective ink and MICR ink for magnetic reading of information. The size of the droplets created by the DigiDot piezoelectric print head varies from 5 to 12 pl. Unlike the printheads of the VarioPrint i300, these heads have improved performance due to the actual resolution of 600 dpi and the ink recirculation realized by PreFire technology.

- PreFire technology . Improved print quality and ink consumption optimization is achieved through PreFire technology. The essence of this technology lies in the fact that during the pause printing ink recycle inside the print head.

The combination of PreFire with a new set of water-based polymer Chromera high pigment inks allows to obtain smooth transitions of tones, stable size and position of the drops on paper. ColorStream can handle paper from 60 to 160 g / m2.

The ColorStream 6000 printing machine runs under the control of the SRA MP controller. Printer data formats are used: AFP / IPDS (IS / 3), PDF (APPE 3.8), LCDS, PostScript, PPML, TIFF, VIPP.

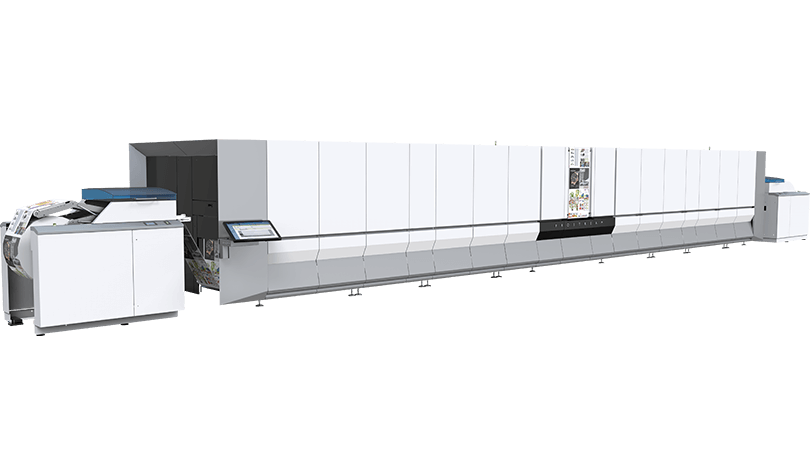

Océ ProStream

At the end of February 2017, the new role-based inkjet printing machine Océ ProStream was introduced at the Swiss Hunkeler Innovationdays exhibition. In this model, the functions used in previous models of Océ printing machines are assembled and improved.

Performance . The maximum printing speed of a strip with a width of 540 mm is 80 m / min, which, translated to A4 sheets, has a capacity of 1076 sheets / min. This is 3.5 times more than the VarioPrint i300. In a month, the Océ ProStream machine can print up to 35 million A4 pages.

Consider what

innovations are implemented in the new press from the company Océ:- Improved DigiDot printhead performance . In contrast to the piezoelectric heads of previous models of printing machines, the droplet size in the Océ ProStream is much smaller and varies from 2 to 6 picoliters (instead of 5 - 12 pl). The actual resolution of the Océ ProStream printhead is 1200 nozzles per inch.

Users will certainly appreciate the reduction in ink consumption with a more flexible transfer of halftones and shades of full-color images.

- Advanced technology PreFire . Just like in the ColorStream 6000, the ProStream head uses the PreFire technology - recycling ink during a print pause. To reduce the likelihood of ink drying in the nozzles, the head has its own cooling system. Due to this, the temperature of the print head does not exceed +32 0C.

- Improved ColorGrip function . The Océ ProStream machine has got the ColorGrip function, like the VarioPrint i300, but with advanced features. In the VarioPrint i300, a special formulation is applied drip onto the carrier. With the expectation that a drop of ink falls on a drop of ColorGrip. In the Océ ProStream machine, ColorGrip is sprayed and performs a dual function. First, the deposition goes uniformly over the entire surface of the carrier, wetting it. And, secondly, the resulting atmosphere from the sprayed ColorGrip formulation improves ink adhesion to the media and prevents ink from drying out in the nozzles.

- New polymer ink. A water-based polymer ink has been developed specifically for the Océ ProStream inkjet printing machine. They have two major differences. This is an improved adhesion to the carrier and the formation of an “adhesive layer” that holds the pigment closer to the surface of the paper. Due to this, there is a more accurate color rendition of images, not inferior in color to high-quality offset printing.

- Innovative non-contact drying. A non-contact flotation dryer is used to dry the paper after printing in the Océ ProStream machine. It consists of a series of heating blocks with opposite-variable arrangement. In the gap between the upper and lower rows of blocks fed sealed paper. Heating paper does not exceed +130 0C. Uniform heating of the tensioned carrier contributes to its rapid drying over the entire surface without spatial deformation. Closer to the exit of the drying unit, several cooling units are installed. There, the heated carrier is cooled to +60 0C. Uniform heating combined with subsequent cooling allow you to remove internal stresses in the paper and stabilize the image after printing. Due to the fact that the movement of the paper strip in the dryer is due to tension, the printed image does not touch anything until it is completely dry. This means that the prints will not be scratches or smeared ink.

In today's configuration, flotation drying can work with paper weighing up to 104 g / m2. By 2018, our developers are planning to make a drying system that can work with paper weighing up to 270 g / m2.

The new role-playing inkjet printing machine Océ ProStream runs on the controller SRA MP. Machine Supported Data Formats: PDF, AFP / IPDS.

The browser-based DFE touch screen is a convenient tool for managing printer jobs and adjusting ink. In the future, developers are planning to work on the DFE via a mobile device. In the current version, DFE supports PDF modification and has its own editing.

The considered models from Océ give an idea of the directions of the modern development of inkjet printing machines of the company for solving various business problems. The first is the improvement of the print heads. Secondly, the printing process itself is optimized, which makes it possible to obtain consistently high results on cheaper paper that are not inferior and sometimes even exceed the quality of offset printing. Thirdly, the improvement of the characteristics of the prepress and post-press related technological processes. In parallel with this, the company is working on the development of ink with better color rendering and properties that improve the quality of inkjet printing. In addition, some upgrades and technical solutions can optionally be used as add-ons on base models of printing machines from Océ.